FortisBC has been cited for two issues related to its.

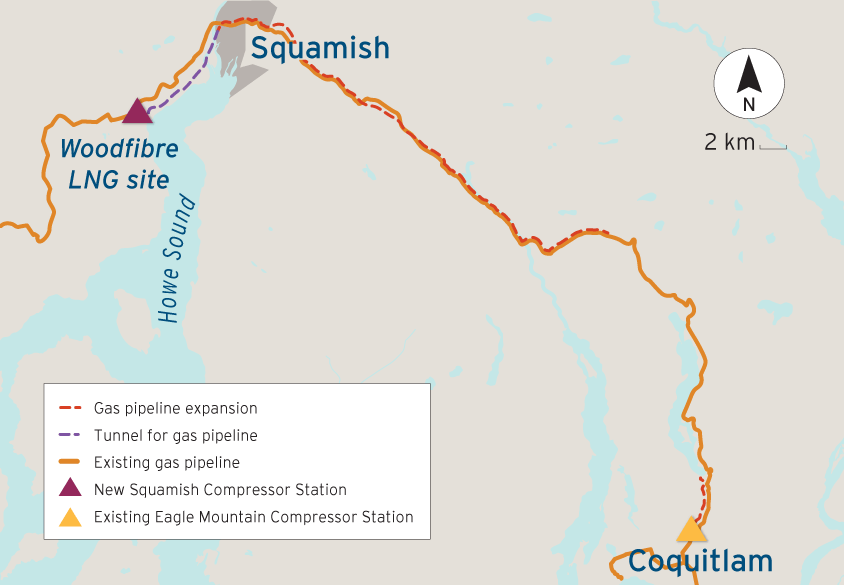

The pipeline, currently under construction, is associated with the liquefied natural gas (LNG) export facility being built on the shores of Howe Sound by Woodfibre LNG.

It involves installing a 47-kilometre natural gas pipeline between the Coquitlam watershed and the Woodfibre Liquified Natural Gas facility southwest of Squamish.

The provincialissued a notice of non-compliance on June 28, related to inspections done by its office on June 18 and 19.

Public notice of this was published on the office's website on July 9.

The EAO inspected the pipeline right-of-way in Coquitlam, project components at the Woodfibre LNG site, and at the BC Rail site.

The first notice of non-compliance issued to FortisBC related to a requirement for secondary containments for hazardous substances, such as engine oil, at FortisBC’s yard at the BC Rail site.

“The officer observed a shipping containe[r] beside the maintenance shop being used to store drums and pails of engine and gear oils. The shipping container did not have any form of secondary containment for these materials,” reads the inspection report.

The report also notes that a concrete containment area wall wasn’t built high enough at the same site.

Regarding secondary containment, FortisBC says that this requirement is an "additional measure over and above the primary containment of such materials, as a precaution to effectively eliminate the possibility of any leakage."

A secondary containment is now in place for the substances identified, a spokesperson for FortisBC said in an email to The ߣÄÌÉçÇø.

"In addition to work underway to raise the height of an existing secondary containment."

The second notice of non-compliance was related to erosion and sediment control measures requiring maintenance on the Coquitlam pipeline part of the ߣÄÌÉçÇøproject.

The inspection report notes that this relates to the clearing of land for the pipeline work where there is a nearby watercourse.

"This maintenance has been completed and the erosion and sediment controls are currently functioning as intended," the spokesperson for FortisBC said.

Tracey Saxby, co-founder and executive director of environmental advocacy group , which has fought the Woodfibre LNG project for more than a decade, sent a letter to the District of ߣÄÌÉçÇøsharing the non-compliance reports.

She also copied The ߣÄÌÉçÇø on that correspondence.

"As council is considering the temporary use permits for FortisBC’s proposed construction yard and workcamp, we felt it was important to highlight these non-compliance issues," she said.

"FortisBC continues to demonstrate that it’s a bad actor."

Asked what was being done to prevent further issues, the FortisBC spokesperson said the company takes any issue of non-compliance seriously.

"We document any instances of non-compliance and review corrective actions to help prevent repeat issues," the spokesperson said.

"More broadly, we regularly take steps to review our work sites and ensure compliance, including internal reviews and inspections on an ongoing basis, and we will continue to take prompt corrective action in the event of future issues should they arise."

The spokesperson said that the company has a "robust compliance documentation and verification process" for the, including a dedicated compliance team.

"We believe in maintaining compliance with environmental regulations and project environmental mitigation plans at all times and in promptly taking corrective action upon issues if or when identified, as demonstrated in this instance."

’Proactively’ inspected

The EAO says compliance and enforcement officers will continue to monitor the sites “to make sure all requirements are being met."

In an emailed statement, a spokesperson for the EAO said that during construction, the pipeline is currently "proactively inspected" by compliance and enforcement officers in a continuous cycle every one to two months.

"The frequency of inspection depends on which phase of construction the project is in as well as the potential for impact and other factors such as seasonal changes like freshet," the spokesperson said, adding that the EAO’s compliance and enforcement officers are responsible for inspecting major projects throughout B.C.

The spokesperson said that "minor non-compliances are common,” and most projects work quickly to correct them once they are discovered by the project’s own compliance staff or by EAO compliance and enforcement officers.

"Major incidents are not common, and EAO compliance and enforcement officers have several enforcement tools available to bring projects back into compliance."

Inspection reports are publicly posted to the